Industrial production of sushi

♦ At the mixing step, you can add preservatives to rice. Using the correct package and storage temperature — the expiration date of ready sushi can be increased to 10 days without freezing and with no loss of taste or flavor profile. When buying the equipment, we can give you technical support and share the successful experiences of our clients. | |

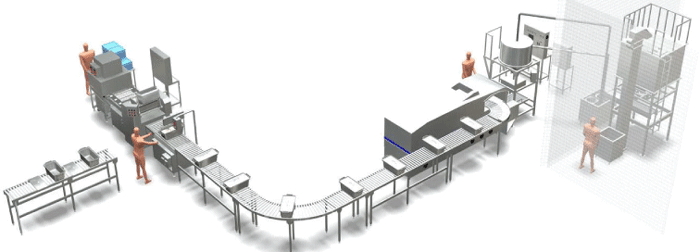

1) Rice cooking: | |

|

1-A) Zone of rice storage | |

| 1. A vertical elevator for rice 2. Storage and dosage of rice 3. A rice conveyor |

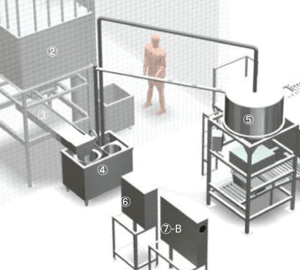

| 1-B) Rice washing and adding of water for cooking | |

| 4. Rice washer 5. A batcher for rice cooking 6. Central control panel |

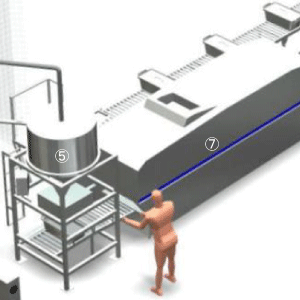

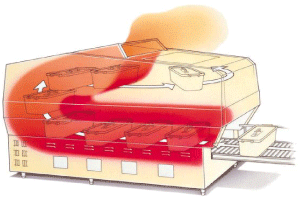

| 1-С) Rice cooking | |

| 7. A gas rice cooker of continuous conveyor type

|

|

2) The next 8-15 minutes — rice settling. 3) Evaporation of the remaining water and final rice cooking. |

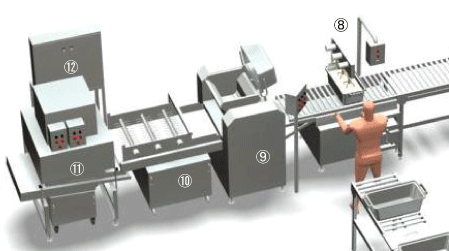

| 1-D) Preparing rice for making sushi | |

| 8. A spray of a vinegar/additives 9. An elevator for rice containers 10. A machine for loosening of the rice |

12. Central control panel | 11. Cooling system of ready rice |

2) Cooking sushi: | |

| |

♦ Among our clients, there are factories with a productivity ranging from 2 to 30-40 thousand rolls per day. The optimum equipment is selected based on: necessary productivity, number of roll types, budget, and prospects of expansion. There is no universal recipe, but there are tested successful solutions. |